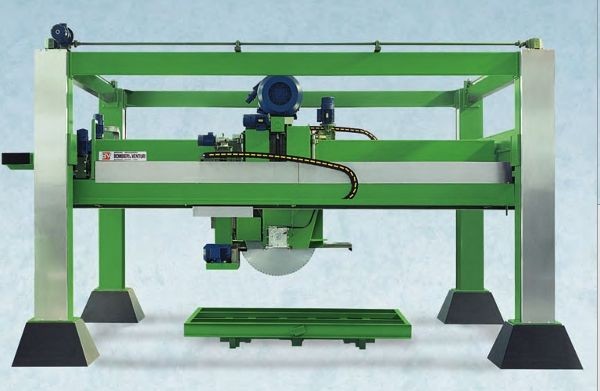

TBV/1300 G TA

Vertical and horizontal simultaneous cut with independent movements.

The machine allows to produce strips from blocks of granite. Its supporting structure is made of electro-welded normalized steel to guarantee the vibrations absorption. The main beam is made of electro-welded normalized steel, stiffened to tolerate high pressure load. The structures are painted with special anticorrosive treatment and are grinded for the perfect alignment of the movement parts. The trolley translation on beam is through lateral containment wheels in oil bath with low coefficient of friction. The remaining movement parts are on grinded precision guides. All the movement parts are operated by PLC and graphic terminal installed on the panel. The switch board is made of sheet steel, thickness 15/10 mm, painted with RAL 7032 paint, IP55 protection level. The disc fall on the trolley is through a self-bearing double-screw device. The machine is supplied with the horizontal disc fixed on an independent beam which allows to simultaneously execute the cut operations.

Fittings:

- spacer flanges for various thickness of cut

(one set is included in the supply)

- stock shaft carrying discs

- number of discs for cut at

- max. vertical discs diameter mm 1300

- vertical discs motor power kW 110

- beam lateral movement motor power kW 0,55

- beam up-down motor power kW 3

- discs up-down motor power kW 0,75

- trolley carrying discs movement motor power kW 2,2

- oil-dynamic plant motor power kW 0,35

- max. height useful cut for disc mm 470

"AUXILIARY BEAM"

- disc diameter mm min. 350 - max. 400

- disc motor power kW 11

- longitudinal movement motor power kW 0,75

- lateral movement motor power kW 0,55

- up-down motor power kW 0,75

- water consumption l/min 460

- total installed power kW 129,9