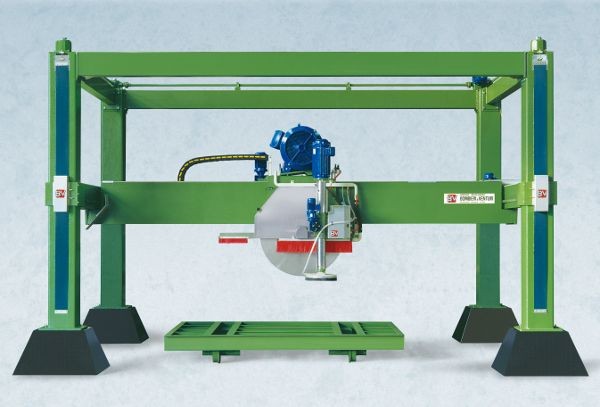

TBV/1300-10 MG - TBV/1600-4 MG

The machine allows to produce strips from blocks of marble and granite. Its supporting structure is made of electro-welded normalized steel to guarantee the vibration absorption. The trolley translation is by a device with ball recycle in oil bath at low friction coefficient. The other movement parts are on grinded precision slides. All the movement parts are operated by PLC and graphic terminal equipped with double programme of cut installed on the panel. The disc fall is by means of big screws on the four columns. The machine is supplied with the horizontal disc fixed on the trolley carrying discs. The switch board is made of sheet steel, thickness 15/10 mm, painted with RAL 7032 paint IP55 protection level. The supplying unit is composed by a magnetothermic switch with shutter locking to avoid the opening of the switch board with tension. It can be restored after opening the shutter, in case of maintenance. To guarantee the operator’s safety, an insulation transformer is installed inside for voltage 380V and output 48V for all the driving mechanisms. The thermal relays and the magnetothermics are dimensioned for every specific motor to protect them in case of anomalies.

- useful cut mm 3500x2300x2000

- number of discs for passing cut (thickness mm 12.5) from 1 to 10 (4)

- vertical discs diameter mm min. 750 - max 1300 (1600)

- horizontal disc diameter mm min. 350 - max. 500

- vertical discs motor power kW 90 (110 for TBV/1600)

- horizontal disc motor power kW 18

- bridge movement motor power kW 0,55

- vertical movement motor power kW 3

- trolley carrying discs movement motor power kW 1,1

- horizontal disc up-down motor power kW 0,55

- displayed horizontal disc up-down

- max. height useful cut for disc mm 470 (620 for TBV/1600)

- water consumption l/min 160

- total installed power kW 113 (133 for TBV/1600)